This information can be found in the Workshop Manual, TSD4400 in Section G. Please do not attempt any work on the hydraulic system without reading or being able to refer to this manual.

WARNING: Do not use equipment that has been used on cars utilising synthetic brake fluid (RR363) when carrying out bleeding operations on cars using Hydraulic System Mineral Oil (LHM). Failure to observe this warning will result in contamination of the hydraulic systems necessitating extensive and expensive rectification.

Introduction

In order to obtain optimum performance of the hydraulic systems, it is essential that they are free of air at all times. The two hydraulic systems are recirculatory and therefore, if air is allowed to enter them at any point it will reduce the efficiency.

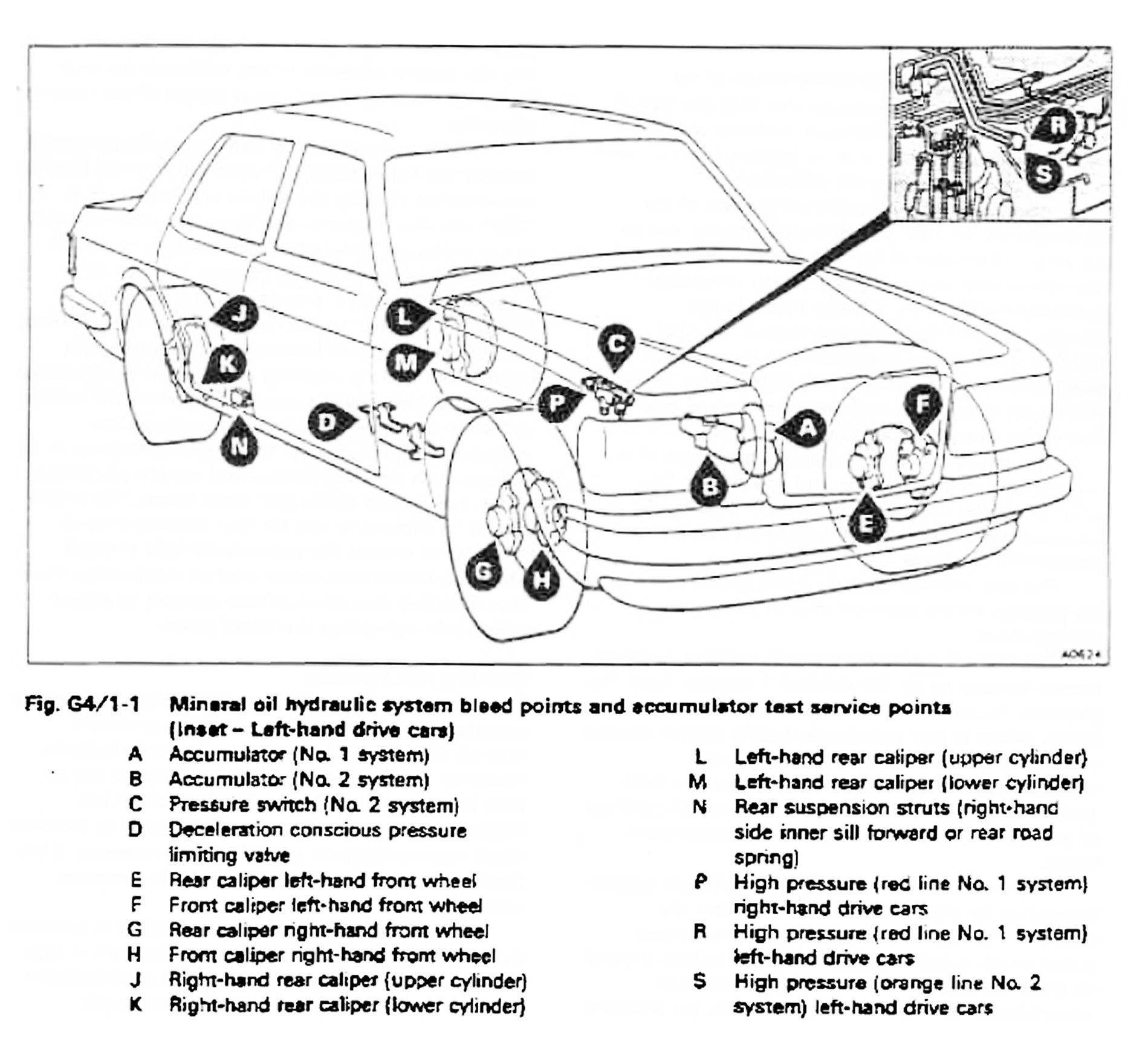

Bleed screws are provided on the side of the accumulators, on each pair of brake calipers, one on the inner sill forward of the rear road spring for the rear suspension struts and one on the conscious pressure limiting valve. A bleed screw is also incorporated into the number 2 system situated adjacent to the pressure switch. The accumulator bleed screws are an integral part of the valve housing and do not require the connection of a bleed pipe during the bleeding operation.

The accumulators are mounted at the rear of the crankcase on the 'B' bank side of the engine (Turbo models) or on the front of the 'A' bank side (Naturally aspirated models). The accumulator for the number 1 system is vertically mounted and the number 2 system accumulator horizontally mounted.

The two hydraulic system mineral oil reservoirs are situated on the left hand side of the engine compartment.

The inboard hydraulic reservoir supplies hydraulic system mineral oil for the number 1 system. From the reservoir, mineral oil is supplied to the front brake pump, which in turn supplies hydraulic system mineral oil under pressure to the vertically mounted accumulator, the upper distribution valve, the front brake calipers on the front wheels, the upper cylinders of the rear brake calipers, and the rear suspension struts.

The outboard reservoir supplies hydraulic system mineral oil for the number 2 system. From the reservoir, mineral oil is supplied to the rear brake pump which in turn supplies hydraulic system mineral oil under pressure to the horizontally mounted accumulator, the lower distribution valve, the pressure switch, the rear brake calipers on the front wheels, and the lower cylinders of the rear brake calipers.

When a rectification has been carried out between the brake pumps and the distribution or height control valves it will be necessary to bleed at all the bleed points in that particular circuit.

However, if a rectification has been carried out between the distribution valves and the brake calipers, it should only be necessary to bleed at the bleed points between the distribution valve and the calipers in the faulty circuit.

Whenever in doubt it is advisable to bleed the complete system.

The power brake circuit should be bled at low pressure, ensuring that the systems are depressurized and the mineral oil levels in the reservoirs are kept above the minimum marks at all stages of the bleeding operation.

To obtain low pressure bleeding of the systems, depress the brake pedal and open the relevant bleed screw before starting the engine and running it at 1000 rev/min. This ensures the accumulator remains at low pressure. Throughout the bleeding operation the brake pressure warning panels marked BRAKE PRESSURE should be illuminated. Only when bleeding the suspension struts should the systems be fully pressurized and the warning panel lamps extinguished.

When bleeding the suspension struts, the interior of the car should be weighted to compress the suspension sufficiently for the height control valves to actuate, thus allowing pressurized mineral oil to flow to the suspension struts and bleed screw. The engine should be allowed to run for four minutes prior to bleeding, to ensure the systems are fully charged. Bleed the suspension struts until all the bubbles have been expelled then allow fifteen seconds to elapse before fully tightening the bleed screw.

Bleeding the systems

The following information is a comprehensive bleeding operation which should be carried out to ensure removal of air from the complete hydraulic systems. However, as previously stated, each system can be bled separately at all points downstream of any replacements or pipe disconnections (refer to Sectional bleed requirements on page G4/1-3 in TSD4400). However, if any doubt exists, it is advisable to bleed the complete system concerned.

Whilst bleeding is being carried out it is essential that the mineral oil level in the two reservoirs is kept to at least the topping-up mark on the level indicator plate, using clean hydraulic system mineral oil.

All bleed screws should be torque tightened in accordance with the figures quoted in Section G19.

When bleeding the hydraulic systems ensure that only equipment suitable for hydraulic system mineral oil is used. See Warning at the top of the page.

Attach a length of bleed tube to each bleed screw prior to the bleed screw being opened. Immerse the free end of the tub in approximately 25.4 mm (1 in) of hydraulic system mineral oil contained in a clean bottle.

Bleed tube attachment is not necessary when bleeding the accumulators, as bleeding is affected internally through the accumulator valve housing, the mineral oil being allowed to flow back to its respective reservoir when the bleed screw is released approximately one revolution (see fig. G7/1-1 in TSD4400).

With the gear selector in Park position and the parking brake applied the following sequence of operations should be carried out (refer to fig G4/1-1 at the bottom of the page), after first noting the following.

System 1 bleed points are A, D, F, H, J, L and N.

System 2 bleed points are B, C, E, G, K and M.

When bleeding the suspension struts extra care should be taken when slackening the bleed screw as the system will be operating at full pressure.

Any hydraulic system mineral oil that has been spilt onto the tyres must be removed. The use of a soap solution and a final rinse with clean water is recommended for this purpose.

Under no circumstances should the hydraulic system mineral oil be allowed to remain on the tyres for prolonged periods as this will cause tyre damage.

1. Remove the gearchange thermal cut-out from the fuseboard.

2. Depressurize the hydraulic systems as described in Section G2/1 in TSD4400. Complete depressurization of the suspension struts is not necessary.

3. Open the accumulator bleed screws, points A and B.

4. Start and run the engine at 1500 rev/min for one minute. Ensure that the facia warning panels marked BRAKE PRESSURE are illuminated.

5. Switch off the engine.

6. Close the accumulator bleed screws, points A and B.

7. Open the pressure switch bleed screw C, allow bleeding to start (right-hand drive cars only).

8. Allow point C to bleed until air free. Close bleed screw C (right-hand drive cars any).

9. Open bleed screws at points D, E and F.

10. Depress the footbrake pedal.

11. Start and run the engine at 1000 rev/min.

12. Allow points at D, E and F to bleed until air free.

13. Open bleed screws G and H allow bleeding to start.

14. Close bleed screws at points D, E and F.

15. Allow points at G and H to bleed until air free.

16. Open bleed screws at points J and K.

17. Close bleed screws at points G and H.

18. Allow points at J and K to bleed until air free.

19. Open bleed screws at points L and M.

20. Close bleed screws at points J and K.

21. Allow points at L and M to bleed until air free.

22. Close bleed screws at points L and M.

23. Release the footbrake pedal.

24. Add weight to the rear of the car to actuate the levelling valves.

25. Allow the systems to pressurize (facia warning panels extinguished).

26. Open the bleed screw at point N, bleed until air free.

27. Close the bleed screw at point N.

28. Check the hydraulic system mineral oil levels in the reservoirs and top-up as necessary.

29. Switch off the engine.

30. Fit a rubber dust cover to each bleed screw. Road test the car.

Sectional bleed requirements

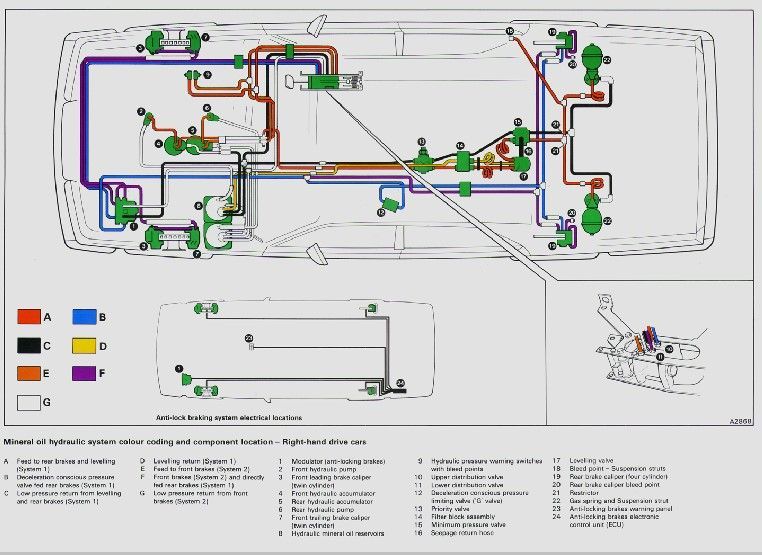

Mineral Oil Hydraulic System Colour Coding and Component Location - Right Hand Drive Cars

This illustration can be found on TSD5000 within TSD6000 which is the workshop manual for cars from 1990 onwards from VIN 30001.

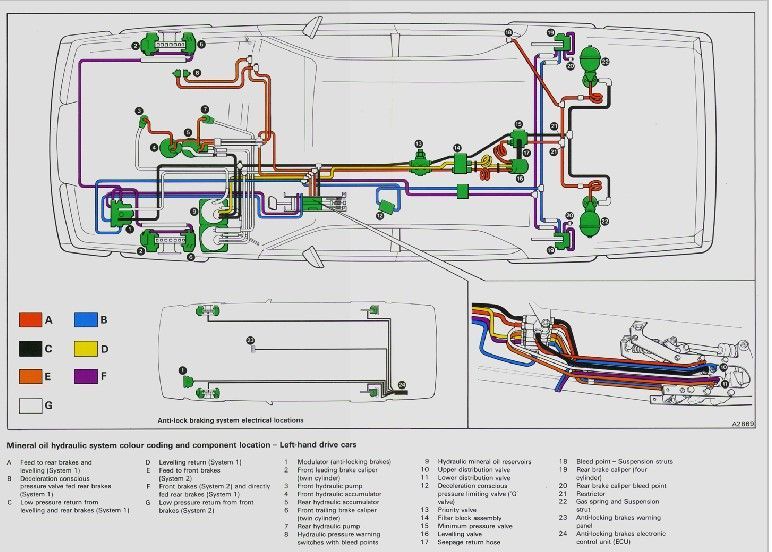

Mineral Oil Hydraulic System Colour Coding and Component Location - Left Hand Drive Cars

This illustration can be found on TSD5000 within TSD6000 which is the workshop manual for cars from 1990 onwards from VIN 30001.

Red pipe line (No. 1 system)

Any pipe disturbed between the inboard hydraulic reservoir, front hydraulic pump, accumulator (vertically mounted), upper distribution valve, and the rear suspension struts.

Bleed the complete system i.e. accumulator, deceleration conscious pressure limiting valve, from calipers on the front wheels, upper cylinders on the rear wheel calipers, and the rear suspension struts.

Orange pipe line (No. 2 system)

Any pipes disturbed between the outboard hydraulic reservoir, rear hydraulic pump accumulator (horizontally mounted), lower distribution valve, and the pressure switch.

Bleed the complete system i.e. accumulator, rear calipers on the front wheels, lower cylinders on the rear wheel calipers, and the pressure switch.

Blue pipe line. (No. 1 system)

Any pipe disturbed between the upper brake distribution valve and front calipers on the front wheels and the upper cylinders on the rear wheel calipers.

Bleed the deceleration conscious pressure limiting valve, the front calipers on the front wheels, and the upper cylinder on the rear wheel calipers.

Mauve pipe line (No. 2 system)

Any pipe disturbed between the lower brake distribution valve and rear calipers on the front wheel and lower cylinder on the rear wheel calipers.

Bleed the rear calipers on the front wheels and the lower cylinders on the rear wheel calipers.

Checking the levels in the hydraulic reservoirs

After bleeding, the following procedure should be used when checking the levels in the hydraulic reservoirs.

1. Switch on the ignition.

2. Depressurize the system by using the bleed screws on both hydraulic accumulators until both brake pressure warning panels are illuminated.

3. Start the engine and allow to run at tick over.

4. Disconnect the lower ends of the levelling valve links and lift simultaneously approximately 38 mm (1.50 in). Hold in this position and allow height to stabilize (this takes approximately 30 seconds).

5. Reconnect the levelling valve links and allow the car to level (this takes approximately 30 seconds).

6. Allow the engine to run for a further four minutes.

7. Check the levels in each reservoir, adjust to the FULL mark if required. Do not overfill the reservoir.

8. Switch off the engine.

9. Seal the reservoirs as described in section G5/1-1 in the workshop manual TSD4400.

9 Jan 2024