This information can be found in the Workshop Manual, TSD5000 in Section G5 which can be found on the IETIS software TSD6000. Please do not attempt any work on the hydraulic system without reading or being able to refer to this manual.

The following information is a comprehensive bleeding operation which should be carried out to ensure removal of air from the complete hydraulic systems. However, as previously stated, each system can be bled separately at all points downstream of any replacements or pipe disconnections (refer to Sectional bleed requirements). However, if any doubt exists, it is advisable to bleed the complete system concerned.

Whilst bleeding is being carried out, it is essential that the mineral oil level in the two reservoirs is kept to the black line on the level indicator sight glass, using clean hydraulic system mineral oil. Reference should be made to Chapter D for approved types.

All bleed screws should be torque tightened in accordance with the figures quoted in Section G22.

When bleeding the hydraulic systems ensure that only equipment suitable for hydraulic system mineral oil is used. See Warning on this page.

Attach a length of bleed tube to each bleed screw prior to the bleed screw being opened. Immerse the free end of the tube in

approximately 25 mm (1 in) of hydraulic system mineral oil contained in a clean bottle.

Bleed tube attachment is not necessary when bleeding the accumulators, as bleeding is effected internally through the accumulator valve housing, the mineral oil being allowed to flow back to its respective reservoir when the bleed screw is released approximately one revolution (see Section G9).

With the gear selector in the park position and the parking brake applied the following sequence of operations should be carried out, after first noting the following.

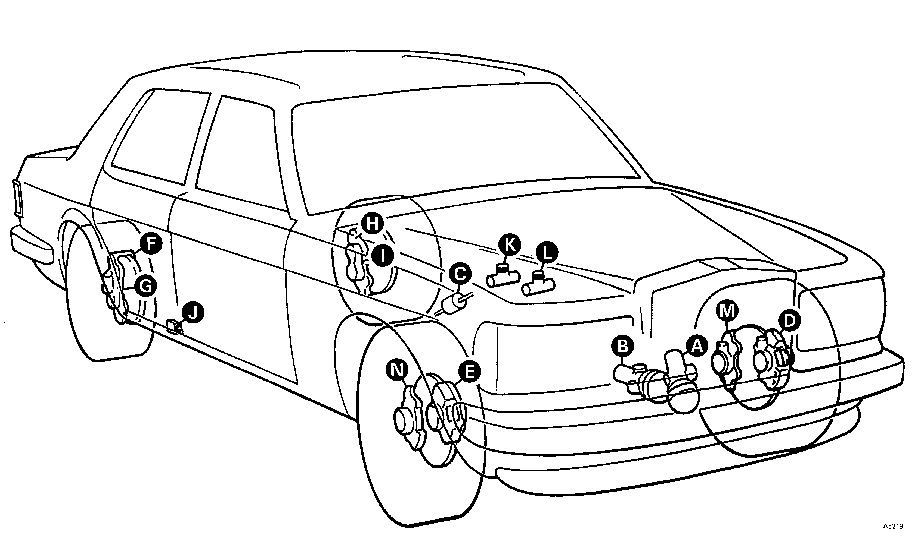

Figure G5-1 indicates the bleed points within both System 1 and System 2.

System 1 bleed points are A,C,F,G,H,I,J and L. System 2 bleed points are B,D,E,K,M and N.

Note: On pre-1992 model year cars, a single bleed screw (D and E) is used at each front wheel with a link pipe connecting the leading and

trailing calipers. On subsequent cars each caliper unit has a separate hydraulic feed and bleed screw ie, D and M (left-hand) and E and N

(right-hand).

When bleeding the suspension struts extra care should be taken when slackening the bleed screw as the system will be operating at full pressure.

Any hydraulic system mineral oil that has been spilt onto the tyres must be removed. The use of a soap solution and a final rinse with clean water is recommended for this purpose.

Under no circumstances should hydraulic system mineral oil be allowed to remain on the tyres for prolonged periods as this will cause tyre damage.

• 1. Remove fuse B1 from fuse panel F1 on the main fuseboard.

• 2. Depressurize the hydraulic systems as described in Section G3. Complete depressurization of the suspension struts is not

necessary.

• 3. Open the accumulator bleed screws, points A and B.

• 4. Start and run the engine at 1500 rev/min for one minute. Ensure that the facia warning panels are flashing i.e. STOP and BRAKE

PRESSURE.

• 5. Switch off the engine.

• 6. Close the accumulator bleed screws, points A and B.

• 7. Open the bleed screws at points C,D,E,K,L,M and N.

• 8. Depress the footbrake pedal.

• 9. Start and run the engine at 1000 rev/min.

• 10. Allow points C,D,E,K,L,M and N to bleed until air free.

• 11. Open bleed screws F and G, allow bleeding to start.

• 12. Close the bleed screws at points C,D,E,K,L,M and N.

• 13. Bleed at points F and G until air free.

• 14. Open bleed screws at points H and I, allow bleeding to start. Close the bleed screws at points F and G.

• 15. Bleed at points H and I until air free.

• 16. Close the bleed screws at points H and I.

• 17. Release the footbrake pedal.

• 18. Add weight to the rear of the car to actuate the levelling valve.

• 19. Allow the systems to pressurize (facia warning panels extinguished).

• 20. Open the bleed screw at point J, bleed until air free.

• 21. Close the bleed screw at point J.

• 22. Check the hydraulic system mineral oil levels in the reservoirs and top-up as necessary.

• 23. Switch off the engine.

• 24. Fit a rubber dust cover to each bleed screw, and replace the fuse in the fuseboard.